Control Systems -Project Design, Coding, Tutorials, and Links

- Introduce the concepts of feeback control

- Proportional

- Derivative

- Integral

- Identify and analyze process dynamics

- Develop and code the algorithms for both the Temperature and Position PID controllers

- Design, construction, and coding of an inexpensive minature thermal chamber control system, a position control system, a 6 degrees of freedom robot, an oscilloscope concept demonstration project, and a spectrum analyzer concept demonstration project. The oscilloscope and spectrum analyzer projects were included as these are electronic instruments that are sometimes used in developing control systems.

- For control systems, explain the concept of optimal tuning using Ziegler Nichols methodology

- Describe, develop and code a fast process control system automatic tuner that will generate the Ziegler Nichols Open Loop tuning constants for the Temperature Control System outline on the project page.

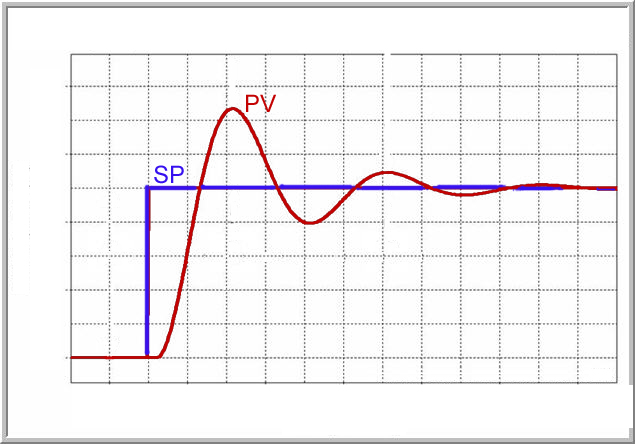

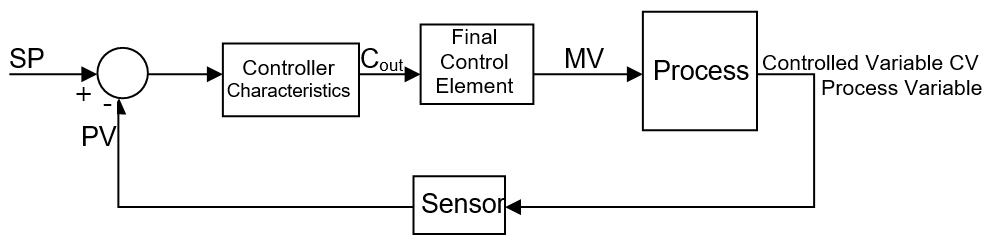

The diagram represents the classical block diagram for a feedback control system. These terms are explained on the first link of the tutorial page called Introduction to Control Systems.